TECHNICAL INFO

Zip – it’s said in a flash, but there’s way more to this little word than you might think. Let’s take a closer look!

ABC... Zip

- Top stopper

- Complete slider

- Teeth

- Chain

- Bottom stopper

- Pin

- Box

- Plastic reinforcement

- Chain width

- Zip lenght

- Body

- Cap

- Puller

Executions

-

CLOSED END

Bottom stopper for secure locking.

-

OPEN END

At the bottom of the zipper, the plastic reinforcement, pin and box are applied -working together to allow the zipper to open fully and smoothly.

-

DOUBLE SLIDER OPEN END

At the bottom of the zipper there’s a plastic reinforcement with two pins attached -one of which locks the slider in place. This setup allows the zipper to fully open in both directions.

-

DOUBLE SLIDER “O” TYPE

“X”-shaped bottom stoppers on both sides -designed for extra grip and secure closure.

-

DOUBLE SLIDER “X” TYPE

Top stoppers on both sides -ensuring a secure hold every time.

Chain types

-

Coil

Coil chain with polyester thread. Light and flexible, it’s well fitting the body and dress curves without scratching. Highly recommended for technical sportswear.

-

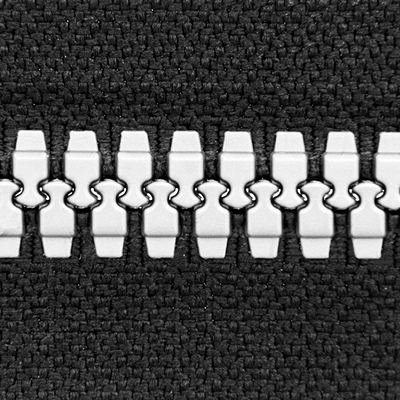

Injected Plastic

The plastic teeth are injected directly onto the tape. The chain is light and resistant, ideal for a sportswear look. The tooth is in the classic shape.

-

Lowered Injected Plastic

The plastic teeth are injected directly onto the tape. The chain is light and resistant, ideal for a sportswear look. The lowered tooth shape is an aesthetic alternative.

-

Symmetrical Injected Plastic

The plastic teeth are injected directly onto the tape. The symmetrical tooth shape is a new aesthetic alternative.

-

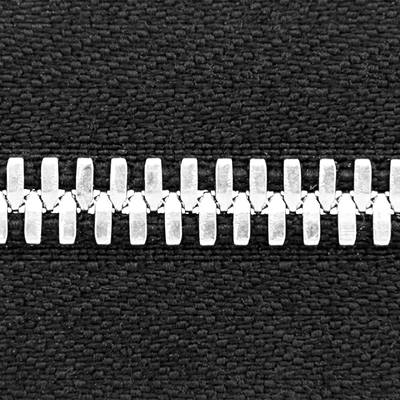

High Quality Zer030 Metal

Chain with metal teeth individually moulded, tumbled and plated before being stapled one by one to the tape. This chain represents the highest quality among metal zippers.

-

High Quality Zer030 Symmetrical

Chain with metal teeth individually moulded, tumbled and plated before being stapled one by one to the tape. The special symmetrical shape gives a higher lateral resistance performance. Moreover, it gets a new aesthetic look compared to the standard one. Particularly recommended for leatherwear.

Chains legend

Chains

| Chains size / type | I invisible | S small | M medium | B big | X extralarge | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4,2 mm | 4 mm | 4,2 mm | 4,5 mm | 4,8 mm | 6 mm | 6,4 mm | 8 mm | 9 mm | 10 mm | 11 mm | 13 mm | |

| invisible | N3 | |||||||||||

| Coil | N4 | N5 | N7 | N9 | ||||||||

| Reversed coil | N4 | N5 | N7 | N9 | ||||||||

| Injected Plastic | F4 | F6 | F9 | 14 | ||||||||

| Lowered Injected Plastic | R4 | R6 | R9 | R1 | ||||||||

| Symmetrical Injected Plastic | E6 | E9 | ||||||||||

| High Quality Zer030 Metal | 02 | 03 | 05 | 08 | 11 | 13 | ||||||

| High Quality Zer030 Symmetrical | J3 | J5 | J8 | |||||||||

Reversible and plastic sliders legend

Reversible sliders

| Reversible sliders size / type | Nylon coil | Injected Plastic | High Quality Zer030 Metal | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N4small | N7medium | N9big | F4/R4small | F6/R6/E6medium | F9/R9/E9big | R1extralarge | 14extralarge | J3/03small | J5/05medium | J8/08big | 11extralarge | |

| W01 | • | • | • | • | • | • | ||||||

| W02 | • | • | • | • | • | • | • | • | • | |||

| W03 | • | • | • | • | • | • | • | • | • | |||

| W04 | • | • | • | • | • | • | ||||||

| W06 | • | • | • | • | • | • | ||||||

| W07 | • | • | • | • | • | • | • | • | • | |||

| W39 | • | • | • | • | • | • | ||||||

| W53 |

•

W61

|

• | • | • | • | • | • | |||||

| W54 | • | • | • | • | • | • | • | • | ||||

| $35 | • | |||||||||||

Plastic sliders

| Plastic sliders size / type | Nylon Coil | Injected Plastic | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| N4small | N4 rov.small | N7medium | N7 rov.medium | N9big | N9 rov.big | F4small | F6medium | F9big | R1extralarge | |

| Auto-lock | • | • | • | • | • | • | • | • | ||

| Auto-lock comby | ||||||||||

| Non-lock | • | • | • | • | • | • | • | |||

| Non-lock comby | • | • | • | |||||||

Notes

STANDARDS

The standard that regulates the physical, dimensional and mechanical performances for the production of our zips is BS EN 16732: 2016

ELIGIBILITY OF THE PRODUCT

Due to the number of possible applications for zippers, we highlight that is customers’ duty and responsibility to check, time by time, if the ordered zipper matches the destination of use.

Examples:

- application on leather/wool

- stone wash

- ready to dye garments

- application on a contrasting fabric colour

COLOR FASTNESS

For MYZIP is mandatory to give to the dyeing process full attention and we can grant to select always the best colouring materials on the market.

Unfortunately is not possible to grant constant colour fastness due to the multiple treatments to which our materials are subject once delivered to our customers.

We therefore ask all our customers to verify under their total responsibility whether the range of fastness of our colours totally satisfy their expectations and needs.

TOLERANCE

The colour tones could change due to wear and tear. We therefore recommend avoiding excessive exposure to the light. The same colours reproduced on differently manufactured tapes or on other yarns will still be on tone but might be perceived as different. As internationally consolidated praxis, we check all colours in a booth with D65 lighting. Observation with other sources of light, either natural or artificial, could affect the assessment the judgment.